When you purchase through links on our site, we may earn an affiliate commission.Heres how it works.

Since becoming sleep writers here at Toms Guide, we talk a lot about mattresses.

However, we had never actually seen the making of a mattress.

Read on to discover the steps needed to make a high-quality mattress and our thoughts on the tour.

What mattresses do 3Z brands make?

Where are 3Z mattresses made?

All of the mattresses manufactured by 3Z Brands are American-made in the companys factory found in Phoenix, Arizona.

The factory is just two-and-a-half years old, with the doors opening in early 2022.

This new, larger site means they can make all the components of a mattress under one roof.

In-house production allows more leeway for experimentation and to respond quickly to any concerns or customer interest.

A step-by-step guide to how mattresses are made

1.

Foam pouring, setting, and cutting

Our first stop on the factory tour was the foam section.

So this is a fitting place to start.

As it makes its way through the line, the liquid expands and rises into foam.

When the foam emerges, it no longer resembles the thick goo that was poured into it.

It now resembles 7ft marshmallows.

The machine, if run non-stop, is capable of making 8,000 queen-sized all-foam mattresses in just eight hours.

Just as buns need to cool, the foam then needs to set.

(Although 3Z does manufacture some all-foam beds, such as thePlank Firm mattresswe got hands-on with).

And as with the foams, these coil layers are also made in-house.

It all begins with a big spool of wire.

Each machine can make a maximum of 160 coils per minute.

The one we watched has racked up 26 million coils in its lifetime thats a lot of beds.

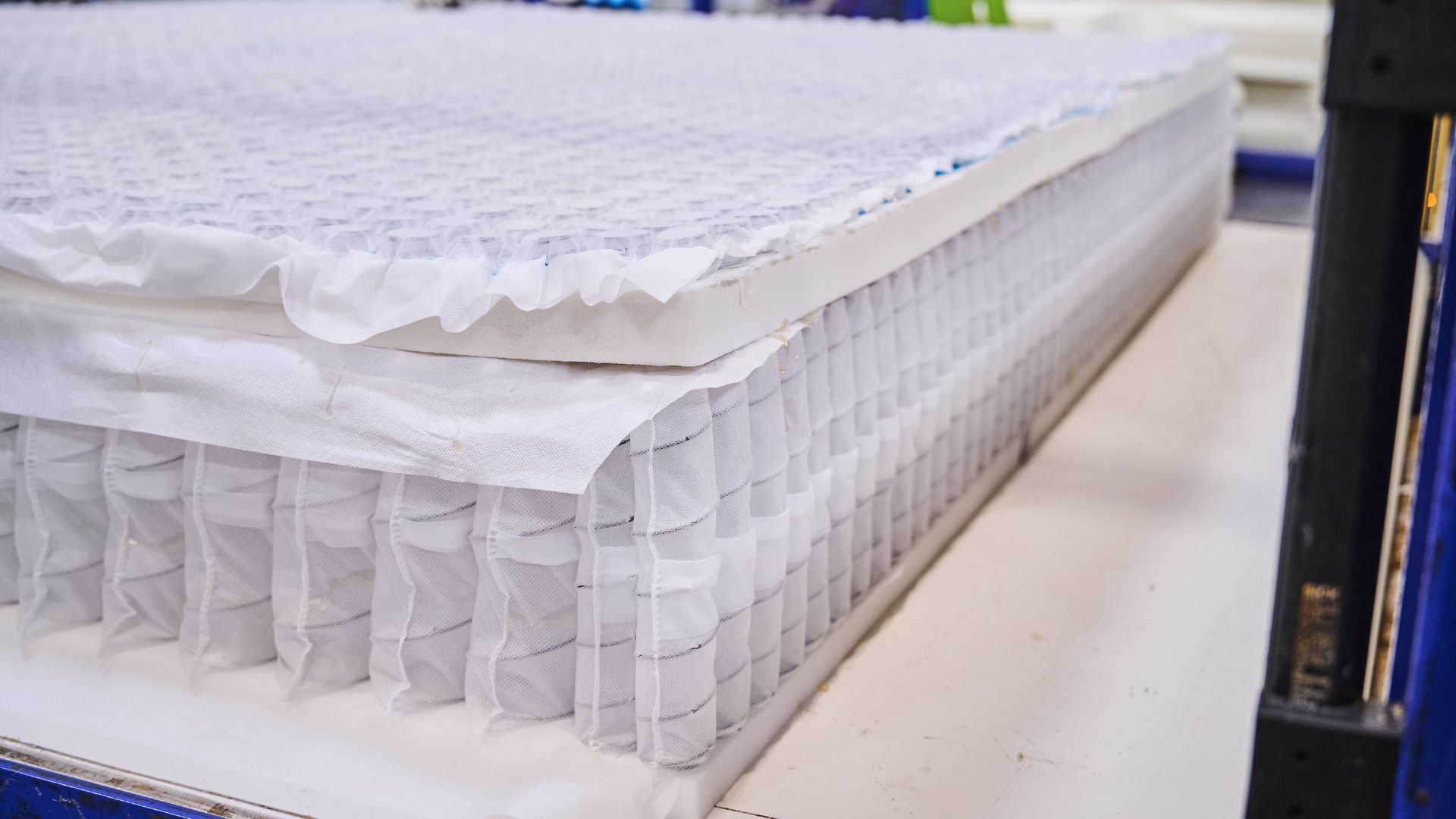

Once cool, the coil is compressed into a fabric pocket.

Every coil is placed in a pocket, with each pocket attached to form a ribbon of springs.

During our visit, the factory was on the cusp of manufacturing its own micro coils.

Until now, these have been shipped in, but theyre set to be made on-site.

The fabric is, however, made off-site.

The quilting takes place on whats essentially a massive sewing machine.

And the quilting pattern is more than just a pretty finish it can affect the overall feel.

The covers are then passed onto the sewing team, to neatly finish the borders.

Lamination and assembly

With every layer crafted, its time to put the mattress together.

It starts with the lamination process, where each foam and coil layer is glued into place.

Like many steps of the process, this was unexpectedly hands-on.

Each layer is stacked, glued, aligned, and lightly compressed to activate the glue.

They know every bed in here.

(And RFID helps keep things running smoothly.)

After lamination, its time to add the covers.

This is also the final opportunity for quality checks.

By this point, its a simple once over to ensure everything is as it should be.

If its not good enough, the mattress will be pulled off.

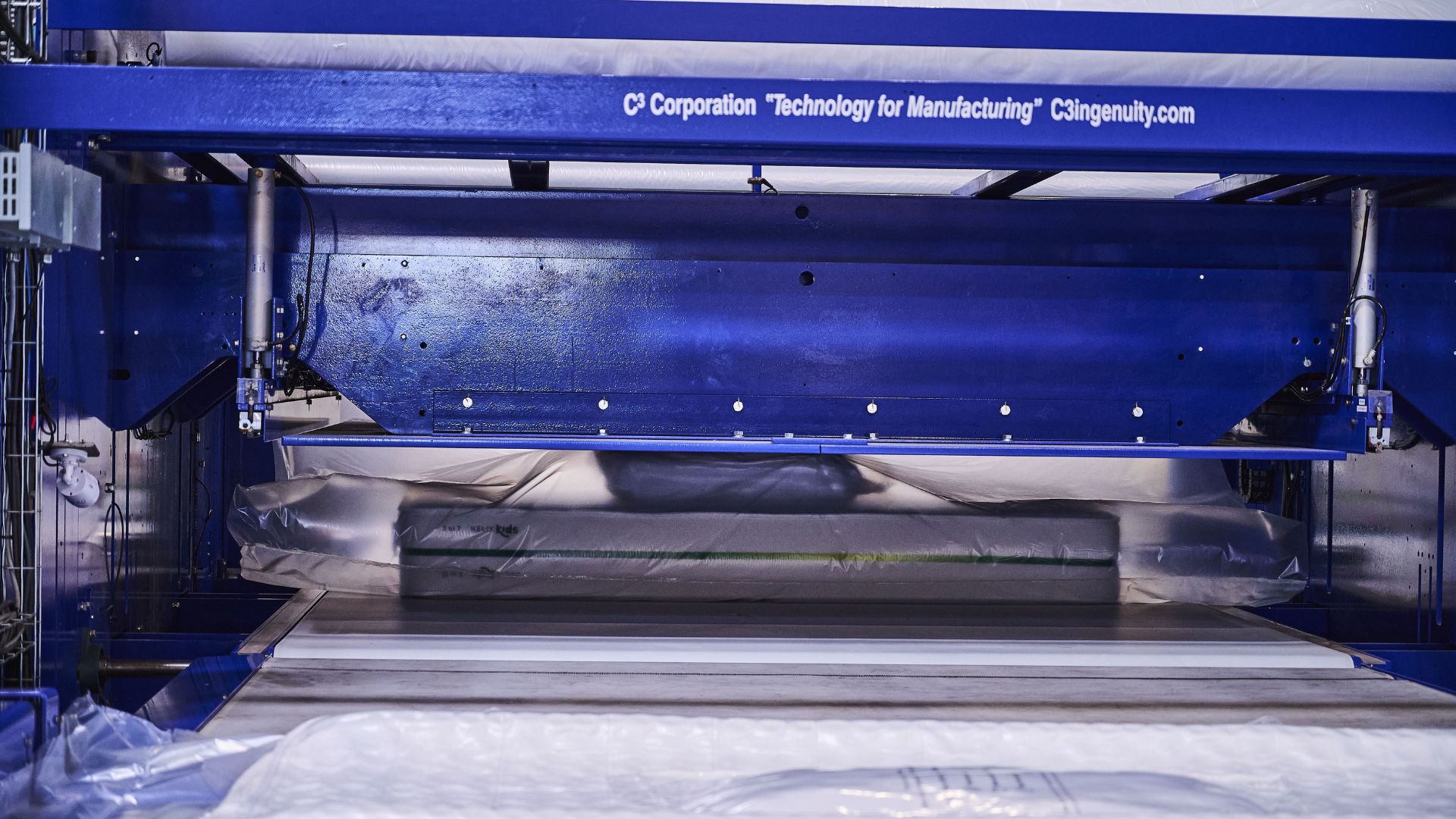

Because now, it gets flattened, sealed, and rolled…

5.

The compress-and-roll-process is a delicate one.

To avoid damage, the rolling and packing is broken down into steps.

The box is then marked with a delivery address label and ready to be shipped to doorsteps across America.